Joining geomembrane pieces together is a critical step in creating a continuous and effective barrier in various applications such as landfill liners, pond liners, or containment systems. There are several methods for joining geomembrane pieces, and the choice depends on factors like the type of geomembrane material, site conditions, and project specifications. However, we must first understand what geomembrane is and its characteristics, types and application fields.

What is geomembrane?

Geomembrane is a material used for engineering waterproofing, anti-seepage, and isolation. It is typically made of plastics such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), and polypropylene (PP). It features flexibility, corrosion resistance, aging resistance, high tensile strength, among other characteristics, and can be chosen in various thicknesses and specifications according to different engineering needs.

Main types of geotextile membrane

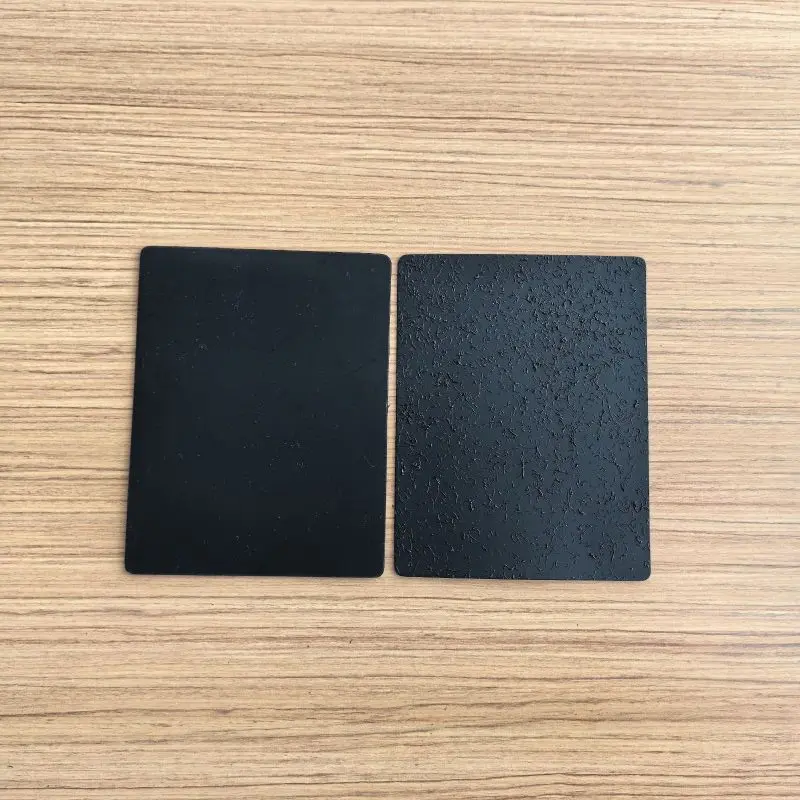

Based on the material, geomembranes can be classified into several main types:

1, High-density polyethylene (HDPE) geomembrane: It has excellent mechanical strength and chemical stability, suitable for anti-seepage projects under various environmental conditions.

2, Polyvinyl chloride (PVC) geomembrane: It possesses good flexibility and weather resistance, suitable for projects with significant changes in groundwater levels.

3, Polypropylene (PP) geomembrane: It exhibits good chemical stability and heat resistance, suitable for projects in high-temperature environments.

The main characteristics of geomembranes

1, Excellent anti-seepage properties: Geomembranes have outstanding waterproof and anti-seepage performance, effectively preventing water, chemicals, or pollutants from infiltrating underground or ground surfaces.

2, Corrosion resistance: Geomembranes can resist the erosion of chemical substances, microorganisms, and other corrosion factors in the soil, ensuring a long service life.

3, Good mechanical properties: Geomembranes have high tensile strength, tear resistance, and puncture resistance, capable of withstanding certain mechanical stresses and deformations.

4, Good aging resistance: Geomembranes exhibit good weather resistance and aging resistance, maintaining stable performance during long-term use.

Application fields

Geomembranes are widely used in the following fields:

1, Hydraulic engineering: Anti-seepage and waterproofing of reservoirs, dams, channels, and hydraulic facilities.

2, Environmental engineering: Anti-seepage and pollution isolation in landfills, sewage treatment plants, chemical plant wastewater ponds, and landfill sites.

3, Transportation engineering: Anti-seepage and isolation in highways, railways, tunnels, etc.

4, Construction engineering: Waterproofing and anti-seepage of basements, foundations, roofs, etc.

How to join the geomembrane piece together

During the construction process, jointing the geomembrane together is very important, the seamless integration of geomembrane pieces is essential for the success of various engineering projects. You can join geomembrane pieces together using the following methods:

1, Heat fusion: Place two geomembrane pieces together and heat the edges using a hot wedge welder or similar equipment to melt them, then press them together to bond. This method ensures good sealing and strength.

2, Adhesive bonding: Apply a special geomembrane adhesive to the edges of two pieces and then bond them together. Make sure to choose an adhesive suitable for the type of geomembrane material you are using and follow the instructions carefully.

3, High-frequency welding: Use high-frequency welding equipment to bond the edges of two geomembrane pieces together by applying high-frequency energy. This method is often used for thicker geomembrane materials.

4, Hot pressing: Place the edges of two geomembrane pieces together and then use a hot press to press them together, bonding them. This method is suitable for certain types of geomembrane materials.

Whichever method you choose, ensure that the geomembrane surfaces are cleaned and prepared before joining to ensure a good bond.

The overlap length of geomembrane

The overlap length of geomembrane typically depends on specific project requirements and application scenarios. Generally, the overlap length should be sufficient to ensure good sealing and waterproofing while considering the material characteristics of the geomembrane and construction conditions.

Typically, the overlap length of geomembrane ranges from 15 centimeters to 50 centimeters. However, the specific overlap length may vary due to different factors such as the thickness of the geomembrane, the type of geomembrane material, engineering design requirements, groundwater level, etc.

For geomembranes of the same thickness, the recommended overlap length is generally between 15-20 centimeters. However, in specific situations such as highly absorbent soils or load-bearing projects, the overlap length may need to be increased accordingly.

For geomembranes reinforced with galvanized steel wire, the recommended overlap length is typically 1.5-2 times the grid size, while for geomembranes without steel reinforcement, the overlap length should be between 20-30 centimeters. Before connection, it is essential to ensure that the membrane surface is smooth and coated with plastic.

If you have any questions about this, please fell free to contact me: Echo: phone/whatsapp:0086-18853127527,email: export@hygeosynthetics.com.

897.webp)

942.webp)

237.webp)